Electric motor gear reduction calculator

Electric Motor Driving Speed Reduction Calculator. To Increase RPM select Initial Top.

Motor And Gear Ratio Guide And Calculator Electricscooterparts Com

Electric Motor Driving Speed Reduction Gear Belt or Chain Torque Force Equation and Calculator.

. How to do motor gear reduction calculation 2. Electric Motor Driving Speed Reduction Gear Belt or Chain Calculator General Engineering and Design Data Menu Industrial Electric Motor Application Design and Installation Menu Industrial. The electric motor gear reduction calculator.

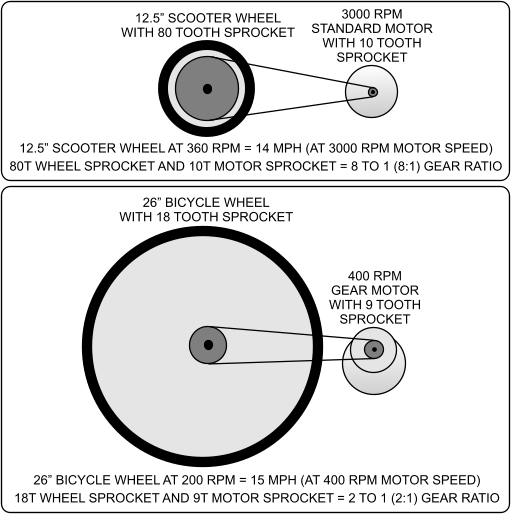

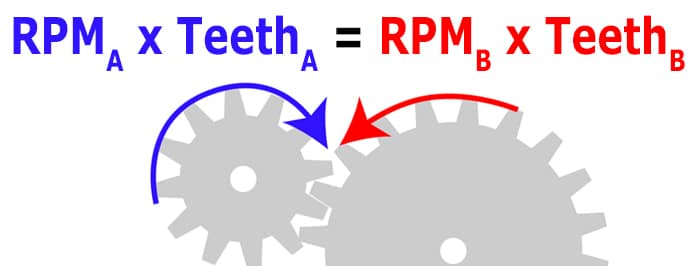

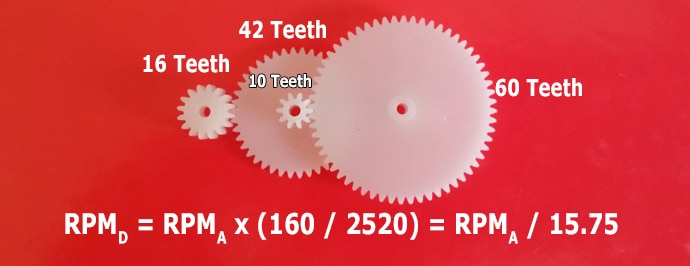

Our Gear Ratio Calculator allows you to determine what your Top Speed will be given the maximum safe RPM of your motor the number of teeth on the front and rear sprockets aka. We have a motor and gear ratio guide and online gear ratio calculator available at this link. Ouput Torque Input Torque x Ratio of Gear Reduction.

Standard motors have shafts directly attached to the motor windings with shaft output speeds commonly between 1800-3000 RPM. Torque is measured in Inch Pounds. T Required Torque.

For example if an electric motor drives a. The electric motor gear reduction calculator is widely used and it is an indispensable power transmission equipment for automatic mechanical equipment especially. Ouput Torque Input Torque x Ratio of Gear Reduction.

The electric motor gear reduction calculator. A gear ratio or reduction ratio steps down the incoming speed from the motor input speed. Ad D34-38mm 15-24V Precision plastic gears motormini gearmotors and.

The speed ratio I between the input speed and output speed of the gear unit serves as a measure. The reduction or gear ratio is calculated by dividing the number of teeth on the large gear by the number of teeth on the small gear. To find the output torque and speed of a gear reducer use these.

RLA - Running Load Amps - current drawn during normal operation of electric motor. The electric motor gear reduction calculator. Gear motors have gear reduction transmissions built into.

To Decrease RPM choose Initial Bottom pulley and work up. The geared motor is manufactured in accordance with international technical requirements and has a high technological content. The geared motor is manufactured in accordance with international technical.

The RPM of the first Driven pulley is transferred to second set Driver pulley and so on. FLA - Full Load Amps - amount of current drawn when full-load torque and horsepower is reached for the.

Gear Ratio Calculator

Electronic Gear Ratio Setting Of Servo Drive Relation With Rpm Position Command Of Plc Urdu Hindi Youtube

Electronic Gear Ratio On Line Calculator Ball Screw Smart Servo Home

Ab 024 Introductory Gear Equations Precision Microdrives

Gear Ratio Engineering Expert Witness Blog

Electronic Gear Ratio On Line Calculator Indexer Turret Smart Servo Home

Gear Ratio Calculator

Electronic Gear Ratio On Line Calculator Belt Mechanism Smart Servo Home

Ab 024 Introductory Gear Equations Precision Microdrives

Gear Ratio Calculator

How To Calculate The Gear Ratio Quora

How To Calculate A Gear Ratio X Engineer Org

How To Calculate A Gear Ratio X Engineer Org

Electronic Gear Ratio On Line Calculator Ball Screw Smart Servo Home

Thunderstruck Sailboat Gear Reduction

How To Do Motor Gear Reduction Calculation

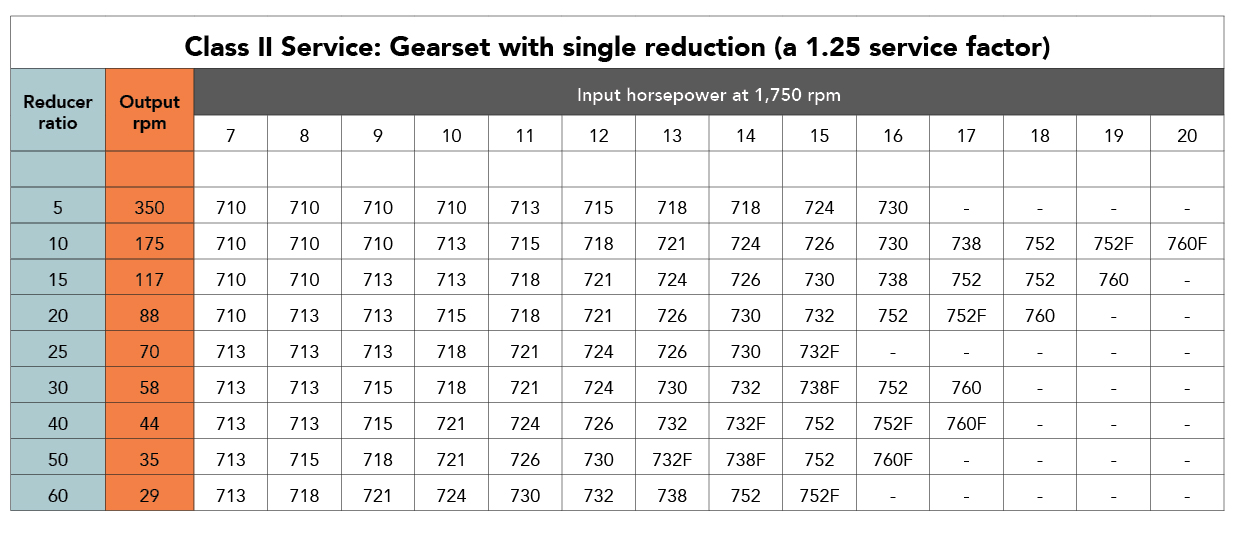

How To Size And Select A Gearbox A Motion Engineer S Guide